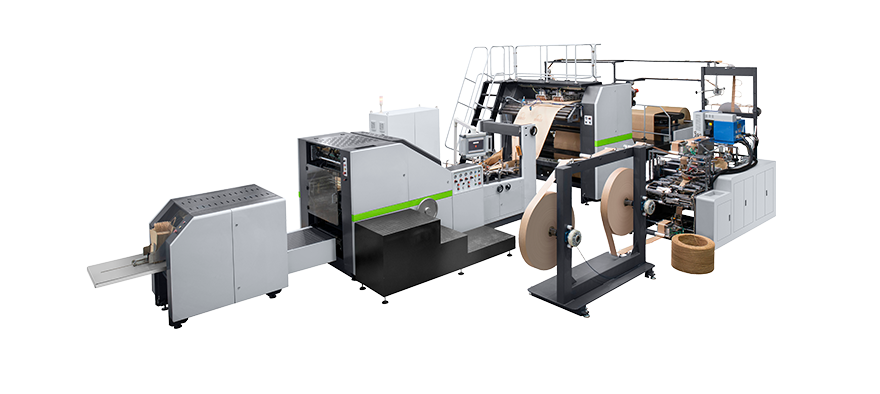

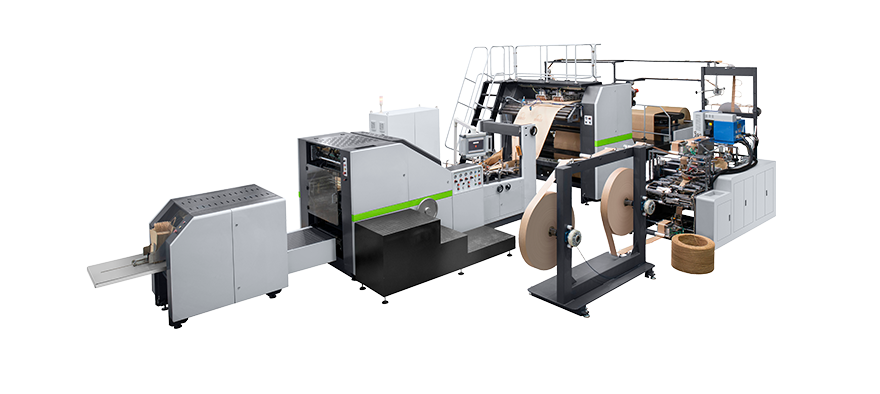

Square bottom paper bags serve across various industries, offering a perfect combination of stability, ample storage space, and enhanced branding opportunities. To achieve consistent and quality production, square bottom paper bag machines appear.

In this blog post, we will discuss the benefits of these bags, key features to consider when buying machines, pricing factors, and success applications.

Benefits of Square Bottom Paper Bags

Enhanced Bag Stability

Excellent stability makes them ideal for carrying heavier items and reducing the risk of contents shifting during transport.

Ample Space for Larger Products

With their spacious interiors, square bottom paper bags accommodate larger products, making them a perfect choice for bulk retail purchases and takeaway food containers.

Improved Brand Visibility and Recognition

More surface area for branding and customization, allowing businesses to showcase their logos, slogans, and designs prominently.

Versatility across Different Industries

Square bottom paper bags find applications in various sectors, including retail, food, apparel, and gifting, adding to their versatility and widespread use.

Benefits of Automatic Square Bottom Paper Bag Machines

1. Automated and Efficient Production

Fully automatic square bottom paper bag machines automate the bag making process, streamlining production, and significantly boosting efficiency. They swiftly produce quantity bags in a short time, saving substantial labor costs and improving overall productivity.

2. Customization Opportunities

Square bottom paper bag machines provide a wide range of customization options, including sizes, handle styles, and colors. This level of customization enables businesses to align the bags precisely with their unique branding requirements.

3. Cost-Effective Packaging Solution

By manufacturing bags in-house, businesses can slash their packaging expenses significantly. Moreover, the ability to control production schedules empowers companies to optimize their resources and respond promptly to market demands, further enhancing cost-effectiveness.

How to Choose a Square Bottom Paper Bag Making Machine

Selecting the right square bottom paper bag making machine is crucial for optimizing your packaging operations. Consider the following key features and specifications:

1. Bag Size and Customization Options

Flexibility in producing bags of different sizes and customization options can cater to diverse packaging needs.

2. Production Capacity and Speed

Assess your production requirements, and choose a machine with the appropriate production capacity and speed to meet your demand efficiently.

3. Paper Weight and Material Compatibility

Ensure that the square bottom paper bag making machine is compatible with a range of paper weights and materials to produce sturdy and reliable bags.

4. Automated Features for Efficiency and Ease of Operation

Look for machines with advanced automation features that streamline the bag-making process, reducing manual intervention and increasing productivity.

5. Durability and Quality of Construction

Invest in a machine built with robust materials and components, ensuring longevity, reliability, and consistent performance over time.

Pricing Factors for Square Bottom Paper Bag Making Machines

Production Capacity and Speed

Machines with higher production capacities typically come with a higher price tag, but they offer greater efficiency and faster output. Buy a suitable machine according to your situation.

Customization Features and Add-ons

Additional customization features impact the cost, but they provide added value in creating unique and functional bags.

After-sales Support and Warranty

Partner with reputable manufacturers who offer comprehensive after-sales support, including technical assistance and warranty coverage.

ROI Analysis and Long-term Cost-effectiveness

Conduct a thorough cost-benefit analysis to evaluate the long-term return on investment and the overall cost-effectiveness of the machine.

Examples of Industries That Commonly Use Square Bottom Paper Bags

Square bottom paper bags are extensively used for packaging groceries, fresh produce, and other retail items. The bags offer durability and convenience for customers to carry their purchases.

Popular for takeout and delivery services, they are used to package a wide range of items, including fast food, bakery products, coffee, and other delicacies.

Use for packaging garments, shoes, and accessories. The bags provide a sophisticated and elegant presentation for high-end fashion products.

Square bottom paper bags provide an attractive and sturdy packaging option for gifts, souvenirs, and unique products.

Package medications, medical supplies, and health products.

7. E-commerce and Online Retail

Square bottom gift paper bag machines produce sustainable and aesthetically pleasing packaging solutions for online retailers.

8. Eco-conscious Businesses - Square bottom eco-friendly paper bag machine

Paper bags are a sustainable alternative to plastic bags, aligning with eco-friendly practices.

Investing in a square bottom paper bag making machine with printing can revolutionize your packaging operations and elevate your brand image. By considering the above information, you can make an informed decision and improve your packaging process. Choose a reliable and reputable manufacturer like us to ensure you acquire a high-quality machine that aligns with your business needs. Contact us today.